Vacuum leaks are your enemy.

Finding them is the real challenge.

- The Isolator allows the operator to check for vacuum leaks by easily isolating possible failure points, eliminating the problem.

- Various factors such as a worn seal, a worn O-Ring, damage to the part, defects in the table surface, etc., may cause a leak.

- With the Isolator, you can quickly locate, “isolate,” and eliminate pesky vacuum leaks, increasing your machine’s overall vacuum and effective holding power for better and faster processing.

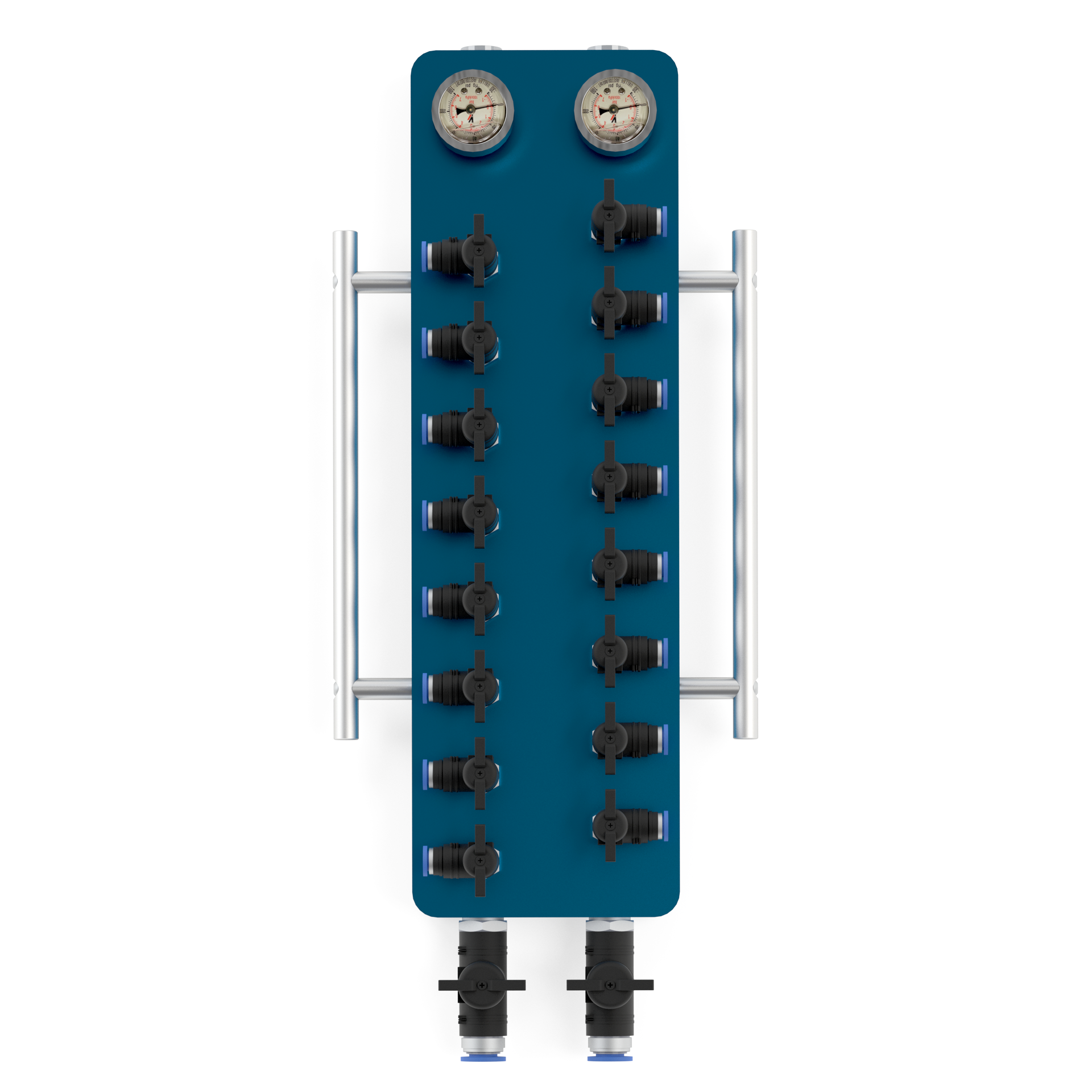

| Part Number | 53-30HG1 |

| Isolator Kit Includes | Vacuum Gauge, Control Valve, Four separate pairs of tube fittings (6 mm, 8 mm, 10 mm, 12 mm, 14 mm, and 1/2″) |

Testing Guide:

- Interrupt the Vacuum Line to Test Part with the Control Valve towards the Vacuum Source

(For Manifolds, ensure that all other Valves to the Manifold are closed) - Connect the appropriate tubing

- Run Vacuum to the Test Part with the Control Valve open

- Once the Gauge shows vacuum, close the Control Valve

- If the dial indicator drops, there is a leak

Troubleshooting:

Manifolds –

- Run regulated air (10-15 PSI) with all valves closed with one inlet open.

- If the machine has a float function, the air is already regulated.

- To identify a leak(similar to checking a propane tank):

- Listen for a hissing noise coming from the source of the leak.

- Apply soapy water to the outside of the manifold along the valves, and watch for bubbles.

- Replace valves as needed

Suction Cups –

- Check air fittings

- Fittings should click when pressed

- Check top and bottom seals

- Seals should sit proud of the channel

- Replace fittings and seals as needed

Downloads

Isolator Kit

$79.00